Image: Atlas Copco

Compressor

Atlas Copco's G and GX oil-injected rotary screw compressors are designed for reliability and efficiency. Will operate continuously in the harshest environments, avoiding costly downtime and production delays.

Image: Atlas Copco

VSD Plus

Our market-leading GA oil-injected rotary screw compressor delivers outstanding performance, high productivity and low cost of ownership - even in the harshest environments.

Image: Atlas Copco

Dryer

Atlas Copco's FX industrial refrigerant air dryers help you avoid the operational costs and downtime caused by corrosion and damage from compressed air condensation

Image: Atlas Copco

Filter

If your application relies on the cleanest compressed air, our line filters and filter cartridges will make that happen with optimal efficiency.

“Using the Atlas Copco line filter cartridges has given us consistent air quality and good efficiency. The push-on filter elements are easy to install.”

Image: Atlas Copco

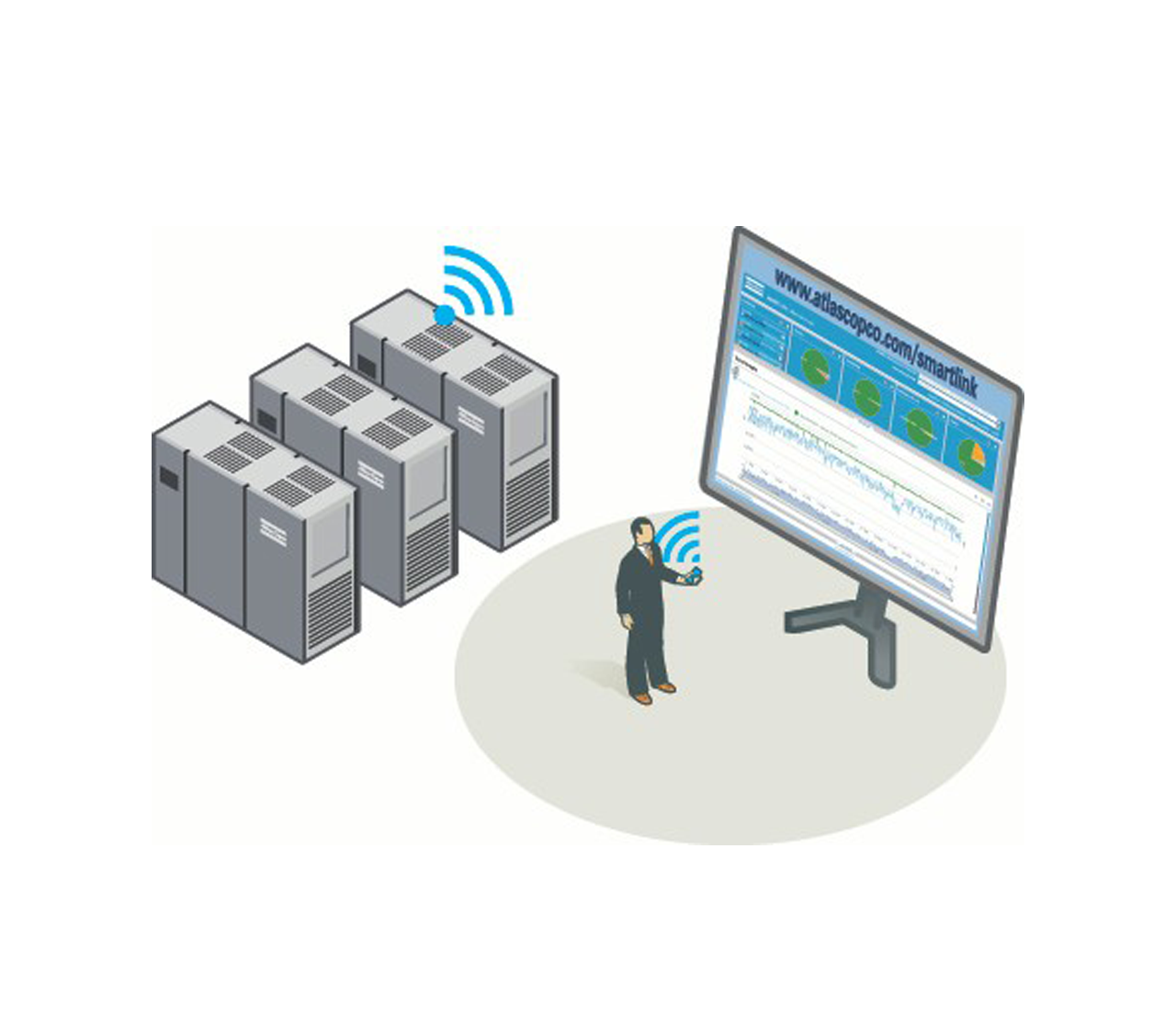

Smart Link

Knowing the status of your compressed air equipment at all times is the surest way to achieve optimal efficiency and maximum availability.

Image: Atlas Copco

AIRnet

AIRnet is a piping solution that guarantees operational excellence for compressed air, vacuum, nitrogen and other inert gas applications. Available in aluminium and stainless steel.

“The use of AIRnet pipework throughout the factory gives us a leak-free environment. We’ve seen savings right from month one as our energy consumption is much lower.”

Image: Atlas Copco

ER

Reuse thermal energy in for other industrial processes that require heat or steam.

“It is amazing how much energy goes up into thin air, and our money with it. Since industries installed Energy Recovery units, they’re reusing upto 90% of compressor heat and really cutting back their costs.”